Moving heavy machinery in factories, workshops, and construction sites has always been a high-risk, high-labor-intensive task. As equipment becomes larger and production layouts more compact, traditional handling methods, such as forklifts or manual rollers, are often no longer suitable. Therefore, electric cargo trolley is rapidly gaining attention as a modern solution for transporting heavy goods.

This article explores how electric cargo trolleys and heavy duty machine rollers are changing how industries handle ultra-heavy equipment, and what factors buyers should consider when choosing the right system.

Why Traditional Heavy Equipment Handling Is Becoming a Bottleneck

Traditional heavy machinery handling methods often have many limitations:

-

Forklifts require wide aisles and clear overhead space

-

Cranes are costly and complex to operate

-

Manual heavy duty machine dollies rely heavily on skilled labor and pose safety risks

Therefore, many factories are turning to electric machine skates rails, which offer advantages such as precise control, compact design, and safer operation in confined spaces.

What Makes an Electric Cargo Trolley Different?

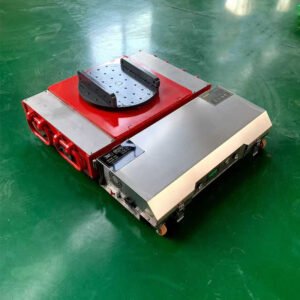

Electric cargo trolleys combine high load-bearing capacity with power drive, enabling operators to move extremely heavy equipment smoothly and precisely. Compared to passive rollers, electric drive systems reduce manpower requirements and improve positioning accuracy during installation or relocation.

Modern systems are designed for:

-

Heavy-duty industrial environments

-

Precise, low-speed movement of valuable machinery

-

Reduced vibration to protect sensitive equipment

This makes electric cargo trolleys an ideal choice for machine installation, production line adjustment, and factory relocation projects.

Load Capacity: From 20 Tons to 80 Tons

One of the biggest advantages of electric vans is their wide cargo capacity. Common configurations include:

-

20T / 25T – compact size (670 × 620 × 165 mm) for medium industrial equipment

-

30T – size 740 × 640 × 185 mm for heavier machinery

-

40T / 50T – size 810 × 800 × 182 mm for large production equipment

-

60T – size 810 × 800 × 195 mm for high-load applications

-

80T – size 1290 × 1154 × 220 mm for ultra-heavy machines

This flexibility allows users to choose the most effective solution without being too large or too small.

Precision Control with Remote Operation

Precision control is crucial when handling expensive machinery. Electric cargo trolleys can be used in conjunction with one of the following two methods:

-

Standard remote control for general applications

-

Industrial-grade remote control for demanding environments and higher safety requirements

Remote operation allows operators to ensure precise movement while maintaining a safe distance, especially in confined installation areas.

Applications

Electric cargo trolleys and heavy duty machine rollers are widely used in:

-

Manufacturing plants

-

Power plants

-

Steel and heavy fabrication workshops

-

Shipyards and construction sites

-

Equipment installation and relocation projects

In these scenarios, heavy duty cargo trolleys help reduce downtime, labor costs, and the risk of equipment damage.

Market Trend: Safer and Smarter Heavy Load Handling

With rising safety standards and factories’ pursuit of greater efficiency, the market is clearly shifting towards powered solutions. Electric machine skates are increasingly replacing traditional manual rollers due to:

-

Greater safety

-

Better maneuverability

-

The ability to handle extreme loads in confined spaces

This shift reflects the broader trend towards automation and intelligent material handling in heavy industry.

Conclusion

Electric cargo trolleys are no longer a niche tool; they are gradually becoming the standard solution for the safe and efficient handling of heavy machinery. Electric cargo trolley and heavy duty machine dolly range in load capacity from 20 to 80 tons, feature compact designs, and can be remotely controlled, bringing significant value to modern industrial operations.

📩 Learn More

For companies planning to install or relocate heavy equipment, understanding the correct configuration of electric cargo trolley is a key step toward safer and more efficient operations.

📞+8615538387011

💌info@sientechnology.com